WRX & STi Sway Bars - Less is More (Added Bonus: thorough explanation of digressive valving)

Contents

– Introduction –

As many of you are aware I have been specializing in Subaru suspension for a long time. I’ve been modifying these cars since the ’90s, and I started my business, Cygnus Performance LLC, back in 2006. Shortly after starting this business I authored the sway bar stickies on all of the major Subaru forums. To this day many Subaru owners modify their cars based on advice I offered in these posts. Unfortunately, as with much of the information on the forums, these posts are very dated.

Back then many people considered me to be the world authority on Subaru sway bars, but the truth is that no matter how many years I spend doing this day in day out there is always more to learn. Just like our products, my opinions and the advice I offer our customers is constantly evolving based on not only my own R&D, but on feedback from tens of thousands of customers. With this post I would like to clear up some of the misconceptions people have about my current views when it comes to sway bars and end links.

– Changes over the years –

These cars come equipped with much larger diameter sway bars from the factory than they did in 2007 when I authored these forum posts. Subaru models that were equipped with 19mm front OEM bars from the factory back then are equipped with 24mm front OEM bars today. Affordable damper technology has also radically advanced. In 2007 I could not sell you a halfway decent coilover set that provided true digressive valving force with proper R&D behind it for an affordable price like I can today.

– Sway bar limitations –

Sway bars are undoubtedly a useful component of the suspension of all WRX and STi generations. With that said it’s important to understand that bigger is not always better. Large sway bars have a lot of inherent limitations, and they introduce several issues. They only provide two benefits which are reduced lateral roll (flatter cornering) and the ability to tune understeer. They have no effect on fore aft body roll (diving under braking and squatting under acceleration). This means that the roll resistance they offer is not a constant. They do nothing as you brake hard for a corner. As you enter the corner the sway bar loads up offering maximum roll resistance mid corner then taper off as you accelerate out of the corner. A sway bar is essentially a spring. Because the rate of this spring is variable it is not always possible to tune your damper with the appropriate amount of rebound and compression force to cope with this spring which is an issue that is exacerbated by increasing bar diameter. To sum it up larger diameter bars are not ideal for many builds because of damping tuning considerations and because your body roll resistance will be inconsistent.

– Reduced droop travel and suspension Independence –

All of this sounds bad enough, but there is more. A large diameter sway bar directly reduces the independence of your suspension. It ties the passenger’s side to the driver’s side which has a number of drawbacks. These corners no longer respond independently without one affecting the other which is not good for handling or ride quality. One of the main drawbacks from a handling perspective is the fact that large bars significantly reduce effective droop travel. Droop travel refers to the suspension’s movement downwards as the suspension un-weights. At autocross events it’s common to see cars tripoding with their inside rear tire floating in the air. Having a large diameter rear sway bar makes this problem much worse. The stiff bar will essentially pull the inside tire off the ground. Stiff coilover springs actually have the opposite effect which is why most of the fastest autocross cars in the country have small bars and stiff springs.

A stiff coilover spring takes full advantage of the independence of the suspension pushing the inside tire to the tarmac which is obviously where you want it. Hitting imperfections in the road on the passenger’s side has no effect on the driver’s side. A stiff coilover spring is also a constant. It doesn’t matter whether you are braking, accelerating, cornering etc. A coilover spring offers an equal amount of roll resistance with fore and aft forces, lateral forces and any combination of the two.

Reducing the independence of the suspension also causes tires to skip over pavement that is not perfectly smooth. This means that if you overdo it with sway bars you’ll actually have less grip on many surfaces. You will have less body roll which may make your car feel like the limits are higher, but in many circumstances they could actually be lower.

– Effects on ride quality –

While it is possible to improve ride quality with coilovers depending on the specifications, it’s important to understand that larger bars always make ride quality worse. How noticeable this is will depend on a number of variables including how large of a bar you went with, what type of surface you are driving on and what type of dampers you are pairing the bar with which brings me to my next point: Putting giant sway bars on stock shocks and springs is never ideal because you cannot increase rebound force to cope with your increased sway bar spring rate.

– What I recommend –

So given everything I have said so far here is my advice in 2022 to all WRX and STi owners looking to improve handling of their car: do things in stages. Start with the most important, most fundamental suspension modification which is high quality coilovers. If your dampers and springs are not right the rest of your handling is not going to be any good. High quality coilovers are 85% of the puzzle, so at least initially, putting a lot of time and effort into that other 15% which is not the weak link off the showroom floor really doesn’t make any sense. This is probably not advice you will get from other vendors. Many of them enjoy selling big comprehensive packages where you are adding lots of bracing and replacing every arm, link, bar and bushing on the car all in one shot. This is a terrible idea because if the final result leaves anything at all to be desired you have no idea what is doing what. Do you need to reduce bar size? Do you need to reduce coilover spring rate? Do you need to change caster or alignment settings? If you have harshness or noise where is it coming from? And most importantly of all – did you even need to spend thousands of dollars on all of these extra components to begin with?

Modern WRX’s and STi’s are night and day massively better off the showroom floor than they once were when it comes to components like bushings and sway bars. Back when I wrote these articles you could walk into a Subaru dealership and buy a brand new GD STi. This was a very long time ago. The sway bars were small, and the bushings were soft. A 2015 STi has a 24mm front bar from the factory and rubber encased spherical bearings for front lower control arm bushings with excellent anti-lift and anti-dive geometry right out of the box. The chassis is incredibly stiff and the 22 WRX further improves upon that. Sway bars are not the weak link that they once were. For the vast, vast majority of VA and VB chassis owners keeping the front bar stock is the best option from a handling standpoint.

There are certainly exceptions to this. If you’re on R comp tires and 16k springs with a caged, gutted car trying to win a time attack it’s another story. You are still always going to be better off getting most of your roll resistance from coilover springs, but of course when you have very stiff coilover springs a larger bar becomes a smaller percentage of the overall stiffness of the suspension. The stiffer springs are able to overcome some of the droop travel limitations by pushing the rear inside tire down to the ground. On these aggressive track builds the larger diameter bars end up functioning similarly to the way OEM bars coupled with more conservative spring rates function. It’s important to be mindful of this so you can keep everything properly balanced based on what you are building your car to do.

– Digressive valving –

I have to talk about digressive valving because the quality, spring rates and valving style of your coilovers all have a direct impact on what your sway bar strategy should be. This is an incredible technology that is really the backbone of everything we do here at Cygnus Performance. It’s a technology that has been around for a long time, but certainly more than anyone else in the Subaru world, we have made proper digressive valving affordable and attainable for the average Subaru driver. Nowadays you will find cheap overseas coilovers that use the word digressive in their title, but in order to implement this technology properly there needs to be a huge amount of application specific R&D put into the product which most of these guys are not doing. I’m very confident that no one is doing it to the level that we are when it comes to Subaru applications. The functional components of the shock also have to be extremely high quality.

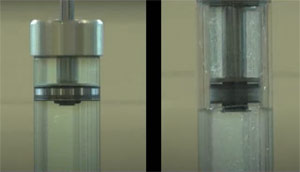

Essentially digressive valving provides variable damping force that is dependent on shaft velocity. As you go into a corner the suspension loads up slowly. This is a low shaft velocity event, so low speed damping force is the damping force that comes into play. With our digressive valving low speed damping force is very stiff which means your car will corner with minimal body roll and maximum driver feedback. This is obviously highly desirable from a handling perspective. If you ever hear me saying that our product offers more low speed control than the competition this is what I am referring to.

On the other end of the spectrum when you are on a bad road or if you hit a pothole or a crack in the road or even cross a curb at the track the movement of your suspension is almost instantaneous. This is a high shaft velocity event, so high speed damping force is the damping force that comes into play. Despite the fact that low speed damping force is very stiff on our product, high speed damping force tapers off and is very compliant. This is the incredible thing of digressive valving. This is the part that gets you the best of both worlds. While you have very little body roll the suspension is still composed and comfortable over almost any surface. Smooth ride quality is the obvious advantage, but there is another advantage. Even if you don’t care about ride quality having suspension that does its job properly is still important. If you hit a curb at the track you don’t want stiff suspension to bounce the car all over the place. You want the suspension to open up, properly absorb the impact and keep everything settled and composed. You want your tires in firm contact with the track rather than bouncing into the air.

– How digressive valving relates to sway bar sizing –

Let’s talk about how digressive valving directly relates to sway bar sizing. If you reduce the independence of the suspension this incredible digressive technology that we are able to provide at a relatively affordable price in 2022 can’t do its job properly. The only way to really understand what this technology is capable of on a street build is to keep your bars stock and get some seat time with your coilovers. Depending on a long list of factors upsizing sway bars down the road can be beneficial, but I always recommend initially experiencing your coilovers without aftermarket bars.

Back in 2007 when we could not provide dampers that were anything close to what I am describing for an affordable price and when the bars that came off the showroom floor were a very small diameter, sway bars were a great first mod for a lot of people. In 2022 when we are talking about the VA and VB platforms they are a great first mod for absolutely no one in my opinion. These cars come equipped from the factory with OEM bars that are larger than many aftermarket bars were for previous generations.

– Increasing sway bar diameter can be beneficial –

I’m not telling people that they should never increase the diameter of their sway bars. What I am telling people is not to start there. You may find that high quality coilovers are all you need, but at the very least if you get some seat time with your coilovers prior to doing anything with bars you will know whether you need to do both bars or just one. You will also know what sizes you need. I love talking suspension, and I’m happy talking with all of our customers about this after they get some seat time with their coilovers if they want to explore the idea of increasing bar size.

– End Links –

I do often sell rear length adjustable end links with 2008+ WRX and STI applications which have multi-link rear suspension. This can be helpful for removing preload from the bar when adjusting ride height. Length adjustable end links can be helpful both in the front and rear if you are corner balancing or significantly changing ride height. But aside from that I would not worry about upgrading end links before doing coilovers either. Personally, I would never purchase an aftermarket end link that does not allow for length adjustment.

– Why we stopped making sway bars –

People often contact me asking if they can purchase the sway bars that we used to manufacture. We no longer manufacture sway bars, and hopefully this article gives some insight as to why that is. From a business perspective it was an excellent part to sell. Sway bars are very simple to design and the manufacturing cost is low. They are very easy to sell since they are inexpensive, and there isn’t a long list of custom options like there is with coilovers. It was a quick and relatively profitable sale, but ultimately the changes Subaru has implemented over the years coupled with the advances we have been able to make to our dampers made this modification obsolete for many of our customers. We don’t spend money on advertising. We rely on happy customers spreading the word. This works so well because our only focus is getting you guys the best possible results for your money when it comes to suspension. If that means discontinuing parts that we once made money on then that is what we do.

– Conclusion –

I’m not telling you to never increase sway bar diameter, but 100% do not start there. If you have any questions we are always happy to help! Thanks for reading.

Geoff